Vegan silk for industrial production

The silk biopolymers from AMSilk can already be found in the aircraft, fashion, cosmetics and crop protection industries, as well as in medical devices.

November 2021

© AMSilk

Interview with Ulrich Scherbel, Managing Director AmSilk GmbH

AMSilk is today the world’s first industrial manufacturer of vegan silk biopolymers. Let’s look at the beginnings: Prof. Thomas Scheibel, co-founder of AMSilk, developed a process to produce spider silk proteins with bacteria and to produce silk from plant raw materials with the help of bacterial fermentation. The patented process is based on the use of genetically modified E.coli bacteria. The bacteria have been virtually reprogrammed to produce spider silk proteins. In a special process, these protein molecules are now used, among other things, to coat medical devices or spun into special fibers. In an interview with Susanne Simon, Head of Public Relations IZB, Ulrich Scherbel, Managing Director of AMSilk GmbH, explains the industries in which vegan silk is currently already being used.

What goal are you pursuing with these innovative silk polymers?

AMSilk has a technology which is able to play an important role in the transformation of the established industry towards a resource-saving economy. We will ramp up production from 40 tons to 10,000 tons per year, giving us the opportunity to work with many cooperation partners from different industries. AMSilk products consist of long-chain silk proteins. These have the property of self-organizing on surfaces and coating them. Because of these unique properties, we see potential in many industries.

© AMSilk

AMSilk increases its production of silk biopolymers from 40 to 10,000 tons per year.

© AMSilk

AMSilk produced a sports shoe with adidas that is lighter, more breathable and also biodegradable.

In which industries is AMSilk currently active?

AMSilk is working with strong brands and partners to launch commercial products in sports and fashion in the first half of 2022 in addition to wristband.

Footwear industry: vegan silk shoe uppers

Together with adidas, we have produced the prototype sports shoe Futurecraft Biofabrics. The shoe consists of an upper material made of 100 per cent Biosteel fiber. The material combines unique properties that are crucial for high-performance. The product is lighter, breathable and biodegradable.

Aircraft construction: weight reduction and fuel savings

In recent years, the aerospace industry has been using less metal to build the fuselage or wing. Instead, it is increasingly using carbon fiber composites. The main reason for this is to reduce the weight of the aircraft and save fuel. The new composite is made with AMSilk’s Biosteel® fiber technology, which enables lightweight construction. The material is thus flexible and better able to withstand repeated loads, such as impacts.

Watch industry: Neu watch straps with AMSilk vegan silk

We have produced wristbands with Biosteel® fibers together with a Swiss luxury watch manufacturer. These are integrated into the traditional fabric. Thus, the bracelets are lighter, more comfortable and more breathable compared to the previous ones made of polyamide.

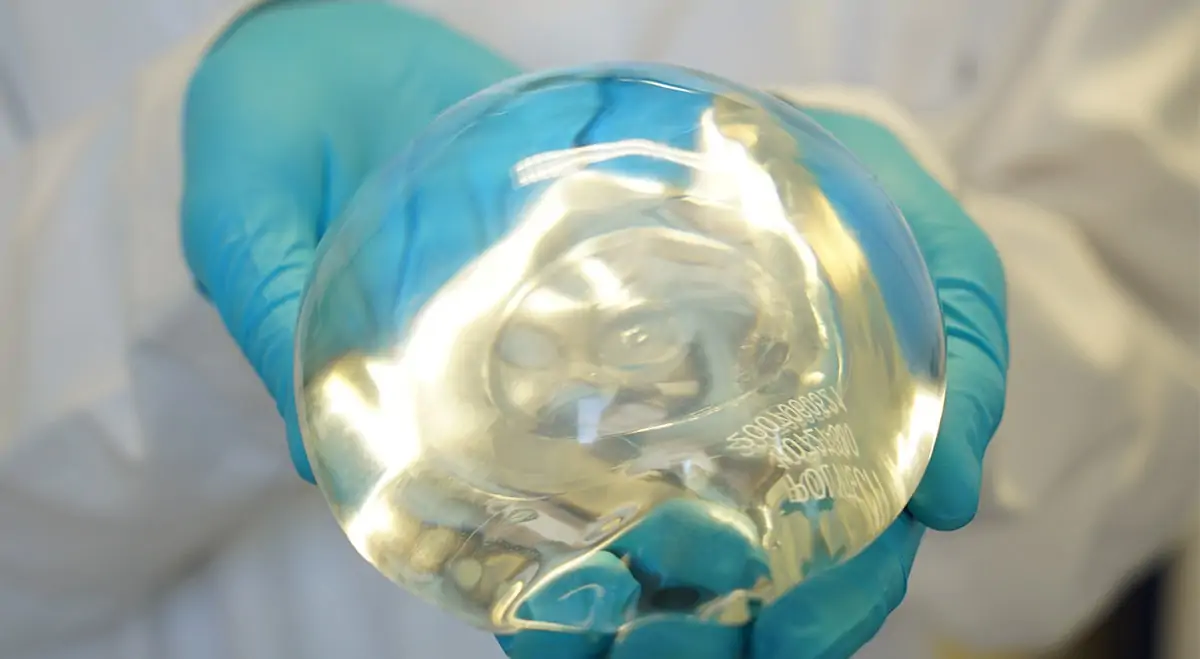

Medical devices: Silk polymers from AMSilk in breast implants

As our silk biopolymers demonstrate antibacterial properties, they are also suitable for use in medical devices. Together with our cooperation partner Polytech in Dieburg, the first silicone breast implants were coated with the silk biopolymers. In a clinical study, silk bioengineered by AMSilk was used for the first time on breast implants in the human body. AMSilk’s unique coating forms a thin and flexible physical interface of silk protein between the silicone surface of the POLYTECH implants and the surrounding tissue. The body recognizes the silk protein as a natural surface, resulting in improved biocompatibility. Preclinical studies have already shown increased tolerability of the silk-coated implants. Therefore, it is expected there will be an improved healing process and postoperative complications (such as capsular fibrosis) can be reduced by this innovative coating.

Fashion industry: organic production without killing silkworms

In the apparel industry, silk stands for the highest luxury. In the conventional production of natural silk, 5.000 silkworms are killed. For the fashion industry, which is increasingly focusing on sustainability, it is especially important that this does not involve the death of any animal. This is not the case with AMSilk’s vegan plant-based silk, as we produce the silk using by organic manufacturing processes.

Cosmetics: Sale of the cosmetics business to Givaudan

In April 2019, AMSilk sold its cosmetics division to the Swiss company Givaudan, one of the world’s largest manufacturers of cosmetic raw materials. These vegan silk biopolymers offer for a broad range of applications across categories such as hair care and skin care with benefits like silk touch, anti-pollution, or color protection of the hair.

Organic crop protection with AMSilk’s vegan silk

So far, we have talked about the fiber and medical technology sectors. In addition, there is another innovative topic at AMSilk. We are already working with the largest manufacturer in the crop protection sector on a product that is sprayed onto plants. The result is that pests can no longer cling to the seed.

© AMSilk

Silicone breast implants with silk biopolymers from AMSilk.

© AMSilk

AMSilk is now the world’s first industrial manufacturer of vegan silk biopolymers.

What is your future corporate strategy?

Our shareholders fully support our vision to make the world’s best and most sustainable biomaterials accessible to everyone. Together, we have the goal of making AMSilk a global leader in biotech performance materials.

In 2008, AMSilk was founded as spin-off from the Technical University of Munich. Thanks to the support of the shareholders AT Newtec GmbH and MIG Fonds, we were able to grow from a humble start-up into a well-established, reputable industry partner in the field of biomaterial products. We are grateful that our initial shareholders support us since the very beginning of our journey. In 2021, additional and renowned shareholders joined the company, supporting us to make the next step.

Together with our existing shareholders and with Novo Holdings, Cargill and E.R. Capital Holding, we accelerate industrialization and expand commercial operations into new markets.

To handle these projects with the necessary professionalism and speed, the number of employees will more than double in the coming months. We will expand the AMSilk team, which has done a great job, especially with experienced specialists from these industries.

What does the location in the IZB mean for AMSilk?

IZB is our home base and offers a fantastic network and a great infrastructure to grow from a start-up to a listed company. As we are in a new phase of the company, we have been looking for a new biotech location. In 2022, AMSilk will be located at Campus Neuried and is looking forward to new conversations and contacts.