Bind-X revolutionizes agriculture with biomineralization

With the new technology, the start-up enables innovative and ecological weed management

May 2021

© LINDIS Biotech GmbH

Interview with Martin Spitznagel, Managing Director of Bind-X GmbH

Agriculture is facing enormous challenges: By 2050, it is expected to feed nearly ten billion people. An additional problem is that energy, water and soils are becoming increasingly scarce. In order not to permanently damage the soil, sustainable management and a reduction of environmental pollution from agriculture is important. Biotech start-up BIND-X has developed a technology that offers an ecological alternative for weed management worldwide. This technology is not only applicable in agriculture, but can also be used in many other industries, such as mining. There, for example, the innovative bio-mineralisation can be used to control the problem of dust efficiently and more cost-effectively. Susanne Simon interviewed Martin Spitznagel, CEO of BIND-X GmbH, for “IZB Biotech News”.

© Bind-X

Martin Spitznagel, Managing Director of Bind-X GmbH. The left pot shows an untreated sample with weeds. The pot on the right shows a sample that has been treated with Bind-X’s ecological bio-mineralisation.

© Bind-X

Various mine dusts solidified by Bind-X’s products

IZB Biotech News: How does Bind-X shape the future of agriculture?

Martin Spitznagel: Agriculture is the foundation of a bio-based economy and the source of safe and nutritious food for the world’s population. In addition, tremendous changes are facing this industry as climate change makes outdoor production more vulnerable and important input factors like water and arable land are getting scarce. Bind-X supports farmers with a new technology that not only helps to control weed growth but also mitigates problems caused by climate change such as wind erosion and water evaporation. Weed management is crucial for sustainable and resource efficient farming and does not need to be based on chemicals only.

IZB Biotech News: How does bio-based weed management work?

Martin Spitznagel:Based on our new technology we can offer a full range of specifically adapted products that are either liquid or solid and can be applied using existing equipment. The driving engine within our products are natural, non-GMO soil bacteria that produce a mineral, which then forms a natural layer within the soil. This physical barrier controls weed growth and helps the target crop outcompete weeds.

IZB Biotech News: How do you plan your market entries?

Martin Spitznagel: We are currently entering the home gardening market in Germany. As there is a huge lack of feasible solutions to control weed growth in gardens on municipal areas, we and our partners strongly believe in a successful market entry. Every passionate garden owner as well as public park managers know about the problem of having to decide between the undesired burning or poisoning of weeds or labour-intensive manual weeding. In addition, we are preparing our market entry in fruits and vegetables. Especially permanent cultures, such as wine and apples, are our primary focus. This will be followed by further crops as we learn from the market and can adapt our technology accordingly. Beside the applications in agriculture, we envision other application areas in the near future.

IZB Biotech News: Can your technology be used in other industries?

Martin Spitznagel: Yes, as a combined technology developer and product provider, Bind-X enables the use of biotechnology in numerous applications and industries. For many industries, significant increases in sustainability can be combined with increased productivity and broadened market perspectives for the first time. For example, dust in open pit mines causes health and safety problems, environmental penalties, and loss of production. The problem is further gaining importance as governments enforce increasingly strict regulations. Current methods, such as spraying water or using chemicals (e.g., salts, synthetic polymers, bitumen) are costly and often harmful to the environment. Bind-X provides the mining sector with the innovative, patented and sustainable dust control product “Bind-DC” with a two-fold value proposition: cost reduction over the cheapest alternatives and an improved environmental footprint.

© Bind-X

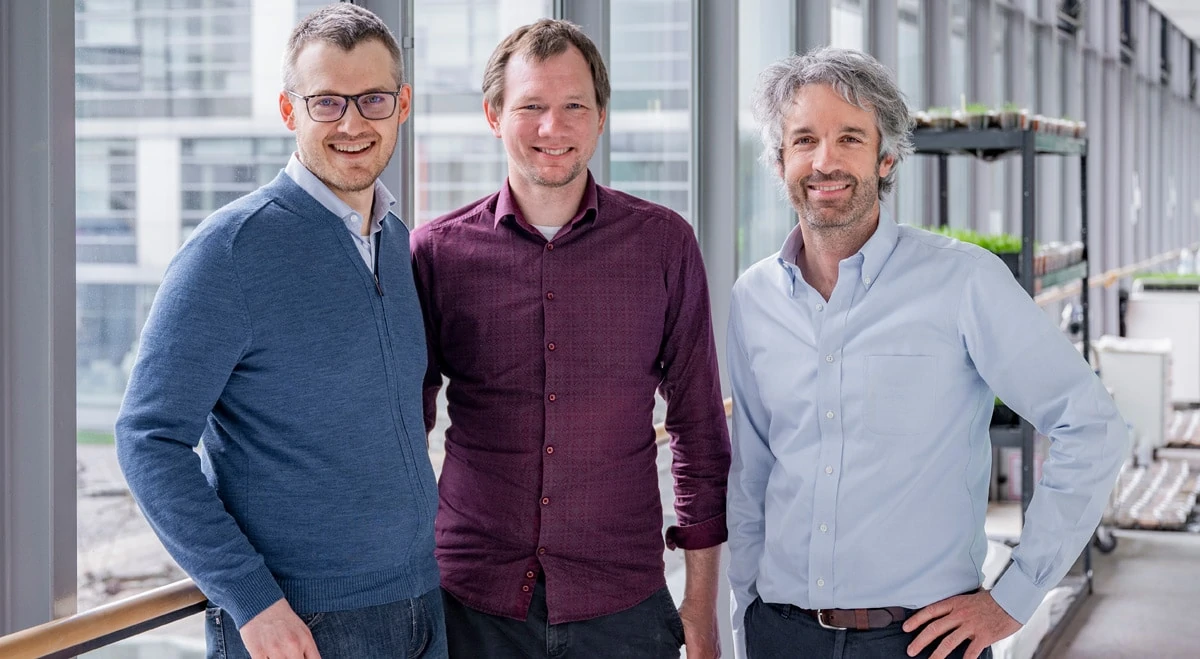

Bind-X-Team: Dr. Luitpold Fried, Technischer Leiter; Dr. Martin Krehenbrink, Produktionsleiter; Martin Spitznagel, Geschäftsführer

© Bind-X

Martin Spitznagel, Managing Director of Bind-X GmbH, in front of bio-mineralisationed soil samples.

IZB Biotech News: The innovative technology turns dust into a solid crust

Martin Spitznagel:Bind-X prevents dust on open mining areas by spraying dust-prone areas with a bacterial solution, which will solidify within 48 hours of application. Bind-DC is based on a biotechnological process, where natural soil bacteria precipitate calcite as a binding agent. In practice, a liquid solution containing a biological component (bacteria) and a nutrient component is applied using existing equipment, such as spray trucks and sprinkler systems. This then forms a solid crust on the surface of stockpiles, tailings, roads, etc. This crust can last up to 18 months and represents a long-term and sustainable solution to the dust problem. Instead of temporarily mitigating the dust problem through water or chemicals, dust is prevented long-term.

IZB Biotech News: Bio-mineralisation is a more cost effective and environmentally friendly process for the mining industry

Martin Spitznagel: Bind-X has developed a proprietary technology platform around this so-called bio-mineralisation, which is compatible with almost any permeable material. Dust in open pit mines causes health problems (for workers and for people living in close proximity), environmental issues (due to heavy metal residues), reduced productivity, and even loss of production as material is lost as dust from stockpiles. Dust leads to total costs for the global mining industry of around 3 billion € per year. The problem gains in importance as governments enforce increasingly strict regulations, not only in developed countries but also in emerging economies. Current methods, such as spraying water or using chemicals (e.g., salts, synthetic polymers, bitumen) are costly, partly inefficient, and often harmful to the environment.

IZB Biotech News: What is your vision for the future?

Martin Spitznagel: Bind-X has focused on industrial applications of biotechnology. Our vision is to improve the sustainability and profitability of established industries by optimizing, adapting, and industrializing biotechnological processes.

IZB Biotech News: What does the location in the IZB mean to you?

Martin Spitznagel: Our company is located in the heart of one of the largest biotech clusters in Europe. Here, we benefit from a creative and entrepreneurial environment and the close proximity to excellent academic and private research. Before founding Bind-X, we evaluated five biotech clusters in four European countries. The decision for the IZB was the right choice to make and is partly responsible for our success.

© Bind-X

Martin Spitznagel, Managing Director Bind-X GmbH, onsite at the Innovation and Start-up Center Biotechnology IZB, with product samples for bio-mineralisation